What Is Cementitious Urethane?

Cementitious urethane is often referred to as urethane concrete or urethane flooring. To put it simply, it is a kind of land; and it also makes it one of the best covers on the market today for many reasons.

What Is Cementitious Urethane Made Out of?

Cementitious urethane is urethane made from Florida cement, water, cane and other recycled materials. This product was originally designed for the food industry to manage the daily washing and heating elements of the installation. Let's look at traditional epoxy flooring systems for comparison. Epoxy flooring FL resin mixes two liquids together to create a reaction. This reaction hardens the soil and creates a beautiful coating known as epoxy. Cementitious urethane, on the other hand, uses two liquids mixed with ordinary cement, known as Florida cement, to create a hard surface.

Which Type of Setting is Cementitious Urethane Used?

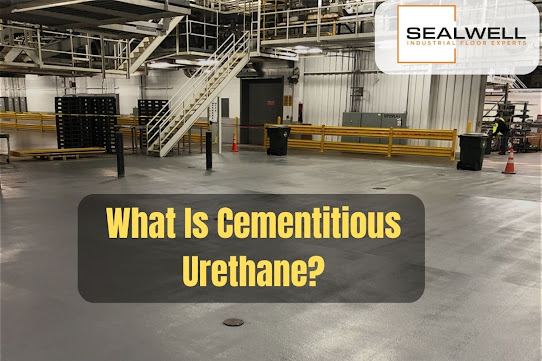

Urethane cement is designed for use on floors in food and beverage processing areas due to its high strength that resists hot and cold washing or regular cycling, in addition to other service conditions and - desirable as chemical resistance. Nowadays, urethane cement is also used in commercial kitchens, restaurant bar areas, office floors, hospitals, healthcare facilities, manufacturing facilities, warehouses, laboratories, offices, chemicals, heavy manufacturing and many other industrial environments that use harsh chemicals during the production process.

Also, read about Everything You Need to Know About Polished Concrete Floors

Benefits of Cementitious Urethane

This bond between water and cement creates a product with many benefits that other soil solutions cannot provide. We have mentioned the 3 benefits of Cementitious Urethane Flooring:

Liquid Barrier

Unlike compaction, this process is impossible with water and other different liquids. This quality makes it the perfect solution for the food industry when it is created. It is also a great choice for any facility that requires daily cleaning and/or sterilization, such as pharmaceutical facilities.

Seamless Application

This system can be installed from the software. Flooring even the entire room can help reduce the level of harmful bacteria or chemicals stuck in the joints.

Thermal Stability

Able to withstand extreme temperatures from -330°F to +240°F, cementitious urethane offers unparalleled heat stability on the market today. These urethanes can also expand and contract at the same rate as concrete, allowing for a lower risk of warping, cracking or cracking.

Is This the Best Option For You?

Cementity urethane is an ideal solution for many industries. Is this method right for your equipment? The price of Sealwell INC. Call us today and we will help you find out!

Original Source: https://bit.ly/3tVBPHD

Comments

Post a Comment